21 Jul, 2025

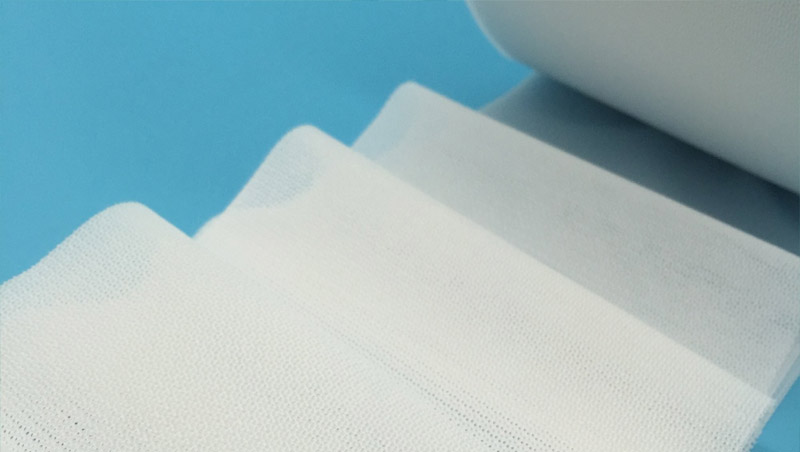

Perforated top sheets are essential components in modern hygiene products like diapers and sanitary napkins, providing comfort, dryness and fluid control. Nikhar Hygiene uses the latest materials such as polyethylene (PE) perforated filmsalso known as “dry nets,” along with perforated non-woven fabrics to ensure best product performance.

What Are Perforated Top Sheets?

Perforated top sheets are technologically advanced sheets in hygienic products used to enable rapid fluid transfer while maintaining a dry and comfortable feel Material choice and perforation technology are key drivers of product performance, i.e., its dryness, breathability, and general hygiene.

Types of Perforated Top Sheets

There are two popular varieties of perforated top sheets employed in the hygiene industry, both with different characteristics:

PE Perforated Films (Dry Nets)

PE perforated films are plastic sheets with specially designed micro-perforations. The sheets are highly effective in allowing fluids to penetrate quickly without wetting the surface, and they are therefore a standard choice for many types of hygiene products. PE perforated films in female hygiene are often utilized as the top sheet and come directly into contact with the skin. In diapers, they are utilized as the Acquisition Distribution Layer (ADL) under a top sheet that is non-woven to facilitate fluid distribution to the absorbent core.

Perforated non-woven fabrics are textile-like breathable goods consisting of bonded fibres with perforations for liquid transfer. They are softer to the touch than PE films, with a cloth-like feel that enhances user comfort. Some sanitary napkins use perforated non-wovens as top sheets as part of their effort to provide a softer more natural feel. They are rarely used in Indian diapers due to their functionality and affordability. They do not constitute part of the product line of Nikhar Hygiene’s diapers. Their use in sanitary napkins is beneficial to users requiring softness along with absorbency.

Applications in Hygiene Products

Sanitary Napkins

The upper sheet of sanitary napkins is the one that comes into contact directly with the skin and therefore its structure and composition are critical to user comfort. PE punched hole films or dry nets are most widely used as top sheets in sanitary napkins by Nikhar Hygiene because they are able to absorb the menstrual fluid rapidly with a dry surface. The dry feel technology reduces discomfort from heavy flow, surface wetness, and odour. And overall hygiene enhancement. Perforated non-woven top sheets, alternatively used on some sanitary napkins, offer a softer, fabric-like feel preferred by some consumers. Both alternatives are satisfactory in regards to fluid transfer and dryness, but the choice is based on market demand and consumer choice.

Adult and Baby Diapers

The uppermost layer of diapers typically contains a gentle non-woven material that is not abrasive to skin, and the PE perforated film is the ADL when placed directly beneath the top layer. The ADL spreads the urine quickly throughout the absorbent core to enable uniform absorption and avoid saturation at places. This faster dispensation reduces leakage and rewetting risk, especially important in adult diaper extended wear or night-time use in infant diapers. By improving dryness and skin health, the ADL enhances both comfort and confidence. Perforated non-wovens are generally avoided in Indian diapers due to added costs and the effectiveness of PE films in this application.

Advantages of Perforated Top Sheets

PE Perforated Films (Dry Nets)

Perforated Non-Woven Fabrics

Conclusion

PE films work best for fast fluid transfer and economy, which is best suited in the case of dry nets in sanitary napkins and ADLs in diapers. Perforated non-wovens, while less trendy in nappies, offer a more luxurious and softer feel for sanitary napkins, which suits users with different tastes. With the support of advanced perforation technology and material sourcing, Nikhar Hygiene not only gets its products to perform better, be more hygienic, and instil confidence but also ensures transparency in material choices for healthcare professionals, distributors, and end-users to allow them to make wiser personal care decisions for improved comfort and reliability with every use.

21 Jul, 2025